Many people can't tell the difference between PE tarp and PVC tarp. Literally speaking, PE and PVC are definitely different.

PE: The chemical name is polyethylene, which is a semi-crystalline thermoplastic material and is the material for making PE tarpaulins. So what are the characteristics of PE?

What is the difference between PVC tarp and PE tarp?

We learned that polyethylene is odorless, non-toxic, feels like wax, has excellent low temperature resistance, good water absorption, good electrical insulation performance, can be used normally at -70 to -100 degrees Celsius, and has good chemical stability.

HDPE (high-density polyethylene) is generally used in the production of PE tarp. This material has a high service temperature, good hardness, mechanical strength and chemical resistance. Polyethylene is suitable for hollow blow molding, injection molding and extrusion of various products (hard), such as various containers, nets, packing tapes, and can be used as cable cladding, pipes, profiled materials, sheets, etc.

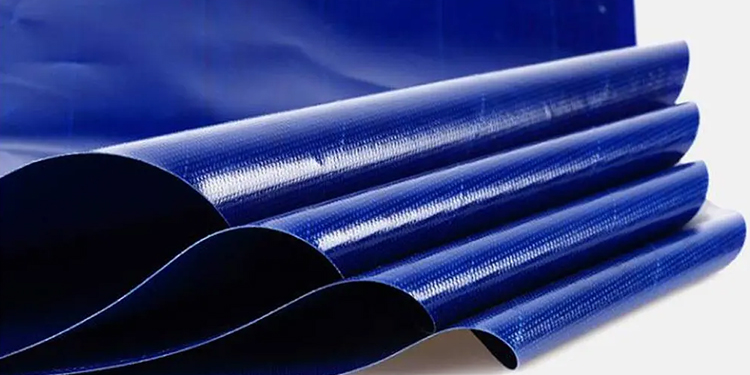

PVC tarp is a plastic-coated high-strength polyester tarpaulin. It is based on high-strength polyester canvas, coated with polyvinyl chloride (PVC) paste resin, and equipped with accelerators, anti-fungal agents, anti-aging agents, antistatic agents, etc. A variety of chemical additives, plasticized at high temperature. It is waterproof, mildew-proof, cold-resistant, aging-resistant, anti-static and other properties; and the breaking strength, tear elongation, and tearing strength of this product are much better than traditional tarpaulins; the appearance of the product is colorful and pleasing to the eye. The surface is specially treated to prevent slipping. It is an internationally popular waterproof cloth with a very large width of up to 5 meters. When the finished product is processed, it can reduce seams and improve quality. It can be heat-sealed and stitched to avoid the worry of water leakage from sewing pinholes. . And according to user needs to produce products with different functions, different colors, different thicknesses.

PE tarp raw materials generally refer to color striped cloth, which is coated with PE film on both sides of PE woven cloth, and polypropylene woven cloth is also used. The production process is: drawing-circular weaving-double-sided coating. This kind of tarpaulin has poor waterproof performance. Generally, it can't guarantee the waterproof performance after one use. The disadvantage is that it is easy to wear and tear. The advantage is that it is light in weight, clean and pollution-free.

PVC tarp is a polyester filament base fabric and double-sided coated PVC paste resin, because it is a dipping process, one-time molding, there is PVC slurry in the gap of the cloth, so the waterproof performance is good, its production process: polyester filament cloth -Plastic dip coating-drying and shaping-calender cooling-winding, now the tarpaulins on the trucks, storage yards and other rainproof products are all made of PVC tarpaulins. PVC material has good rain resistance, PVC has good fatigue resistance, and the anti-aging of PVC tarpaulin is much better than PP and PE tarpaulin.